Demystifying the Diagnostic Process

Demystifying the Diagnosis Process

Diving into the Complexities of Automotive Diagnostic Procedures

Introduction

In the world of automotive repair, accurate diagnostics form the cornerstone of effective problem-solving. From the most basic to the most advanced vehicles, the diagnostic procedure serves as the compass that guides mechanics toward identifying and rectifying issues. This article explores the multifaceted nature of automotive diagnostic procedures, delving into the processes, tools, technologies, and expertise involved in deciphering the enigmatic language of vehicle troubles.

Diagnostic Tools and Equipment

Diagnostic tools are the gateways to unraveling the mysteries concealed within a vehicle’s systems. From basic handheld scanners to complex computerized systems, these tools communicate with the vehicle’s onboard computer, accessing fault codes and providing valuable insights into potential problems. OBD-II (On-Board Diagnostics) scanners, multimeters, oscilloscopes, and specialized manufacturer-specific diagnostic systems are just a few of the tools used by mechanics to initiate the diagnostic procedure.

Scan Tool Connected to OBD Port

Data Interpretation and Analysis

Once data is gathered from diagnostic tools, mechanics embark on the intricate journey of interpreting and analyzing the information. Understanding fault codes and data streams requires expertise in automotive systems and a deep knowledge of the interactions between various components. Skilled mechanics can translate the abstract numerical values and codes into actionable insights that guide their diagnostic decisions.

Symptoms vs. Root Causes

One of the most challenging aspects of diagnostics is distinguishing between symptoms and root causes. Just as a doctor treats the underlying illness, rather than merely alleviating symptoms, mechanics must identify the true source of a problem to prevent recurring issues. This requires a meticulous approach, often involving a series of tests and examinations to pinpoint the precise malfunctioning component.

Vacuum Gauge used to check base Engine Vacuum

Systemic Approach

Modern vehicles are intricate systems comprised of mechanical, electrical, and electronic components. A systemic approach to diagnostics entails understanding the relationships between these components and recognizing how a single fault can trigger a cascade of problems. Diagnosing issues in one system might reveal interconnected problems in seemingly unrelated areas.

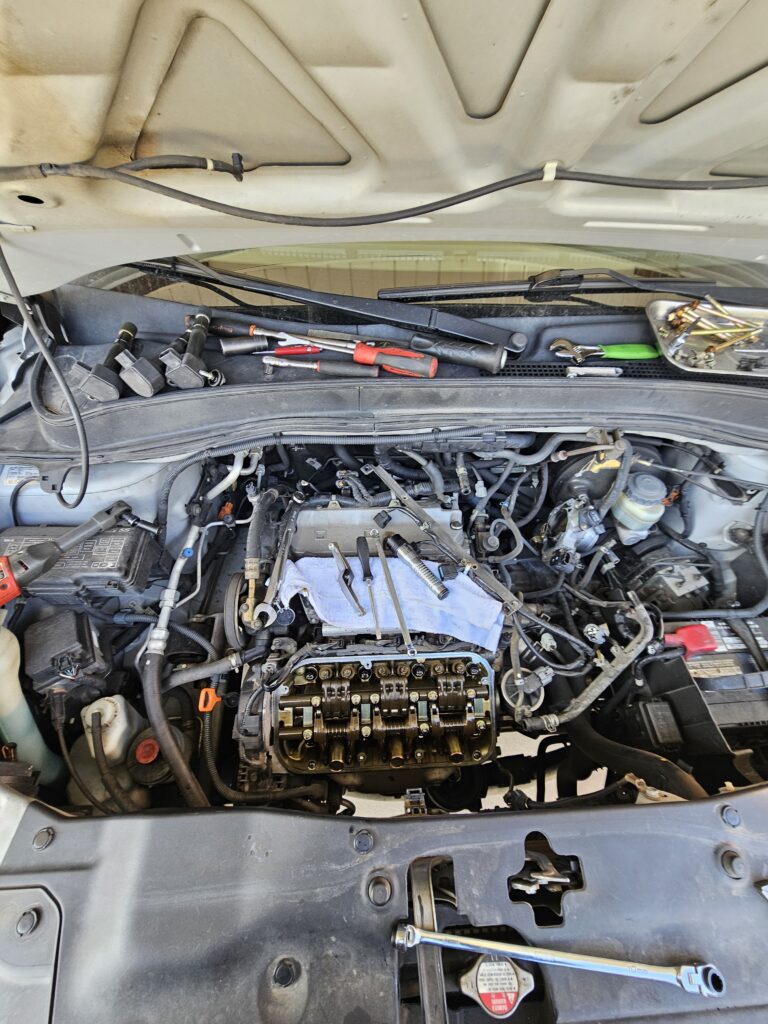

Engine Valve-Lash Inspection

Data Recording and Documentation

Diagnostics are not only about the present moment but also about building a repository of knowledge for future reference. Recording data, including fault codes, test results, and observations, serves as a valuable resource for mechanics. This data can provide insights into recurring issues, help in spotting patterns, and aid in making informed decisions during future diagnostics.

Scan Tool Code Report

Human Expertise and Experience

Behind every successful diagnostic procedure is the human touch of expertise and experience. A seasoned mechanic relies on their intuition, developed through years of hands-on work, to guide them in the right direction. This intangible skill often proves invaluable, especially when confronting complex issues that might not have straightforward solutions.

Smoke Testing an Emission System Leak

Continuous Learning and Training

Automotive technology evolves rapidly, introducing new components, systems, and diagnostic challenges. As a result, mechanics must engage in continuous learning and training to keep pace with these advancements. Training programs, workshops, and staying updated with the latest service bulletins from manufacturers are crucial for maintaining diagnostic proficiency.

Collaborative Diagnosis

In certain cases, a single mechanic’s perspective might not suffice. Collaborative diagnosis involves sharing information and insights among a team of mechanics. This approach taps into the collective knowledge and experiences of a group, fostering innovative solutions and increasing the likelihood of accurate diagnosis, especially for perplexing issues.

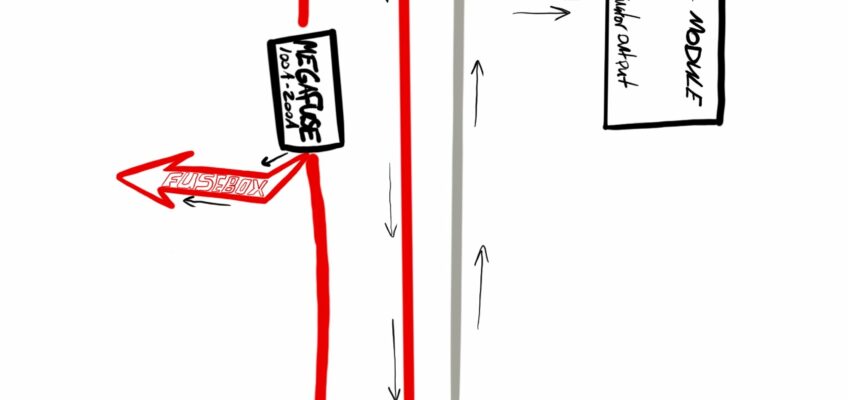

Complex Wiring and Electronics

Modern vehicles are heavily reliant on complex wiring and intricate electronic systems. Diagnosing issues in these areas requires a deep understanding of electrical principles, circuitry, and software interactions. Mechanics must navigate through miles of wiring and numerous sensors, all while ensuring that their diagnostic efforts do not inadvertently create new problems.

Electrical Testing a Faulty Horn

Non-Visual Diagnostics

Not all diagnostic challenges are visible to the naked eye. Some issues, particularly those related to engine performance or emissions, might not manifest in physical form. In such cases, mechanics rely on specialized tools that measure emissions, exhaust gases, and engine performance parameters to identify hidden issues.

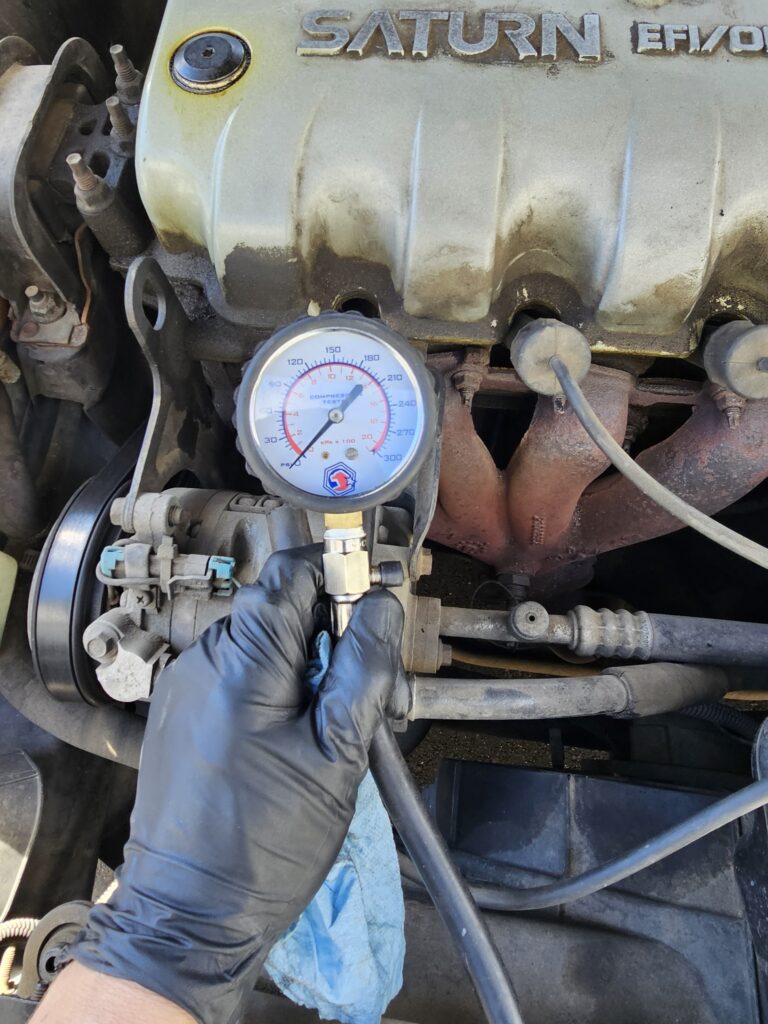

Compression Testing a dead cylinder

Conclusion

The automotive diagnostic procedure is a complex and dynamic process that goes far beyond simply plugging in a scanner. It encompasses a myriad of aspects, from the tools used and data interpretation to human expertise and collaborative approaches. The evolving landscape of automotive technology further amplifies the intricacies of diagnostics. An effective diagnostic procedure requires a blend of skill, knowledge, and technological prowess—a testament to the dedication and ingenuity of mechanics who strive to keep vehicles running smoothly in the face of ever-evolving challenges.

As some one who has no clue about how a car works and or what the procedures are when I bring my car in with issues this was a diamond in the ruff to stumble on.

I love how you have broken down the steps you take as a mechenic to find problems and how you diagnose them.

It gives much more insight on what you do behind the scenes. Thanks for a great read.

With the level of AI development, diagnosing problems with cars using equipment and gadgets will likely get better and better. However, I agree with you that human experience, skill, and intuition will still play a crucial role in resolving problems with cars, particularly complex problems. Mechanics once had to do some work on the fan belt adjuster /pulley system in my car. It kept coming loose because the bolt kept breaking so they had to lift the engine to gain good access to fasten the bolt properly. However, when they reinstalled the engine, it wouldn’t start despite all the efforts of the automotive electrician on site. The electrician then called a senior colleague who also tried but failed. You can imagine how concerned I had become at this point. We had to eventually get an even more experienced technician who got the car working in less than 30 minutes.

Thank you for this informative post. I had always felt that cars had just electrical and mechanical components. I just learned in this post that there are also electronic components.